STU McINTOSH

In 2014 I was at a crossroad in my career and unsure of my next move. My situation was awkward and not one that could be openly discussed. A change was inevitable; I knew wherever I landed would be the last stop in my career and I did not want to be known as a “hired gun.” I put together my list of non-negotiables. I wanted to be part of a team and to be recognized for my efforts. Lastly, I wanted to be given more responsibility. Money, while important, was not a driving factor behind my decision to join the Horwitz team.

Over the next month, I met with Bill McKoskey on multiple occasions and discussed my desires at length. The deciding factors behind my decision to come to Horwitz were that our core values aligned, ownership works hand in hand with the rest of the team, and they have a flat organizational chart. We came to employment terms and I have not looked back since.

During the last several years, we have seen many significant changes at Horwitz. The first one that comes to mind is the embracing of our culture of safety. Over the last five years, we have exceeded the national average for specialty contractors. I am proud to say our 2017 recordable incident rate was 1.21. Horwitz has hired a Quality Control Manager and instituted rigorous quality control programs and procedures. This process has cut down on punch list items and warranty claims resulting in an improved end product for the customer.

In July 2017, Horwitz management took a quantum leap and purchased a new building. This gave Horwitz 20,000 plus square feet of office space and 60,000 plus square feet of warehouse, fabrication, and storage area serviced by a 5-ton overhead crane. Within the new facility, Horwitz has made key investments in fabrication equipment for plumbing, insulating, pipefitting, and most recently sheet metal mechanical work. In addition to the above, we have implemented a tool tracking system and acquired a robust inventory of state-of-the-art tools and technology. To support our pre-fabrication to field effort, we have made a concerted effort to integrate experienced union trades professionals to complement our in-house engineering/design group.

One does not thrive in business for 100 years without maintaining a favorable culture. And lastly, we are not focused on becoming the largest firm in town – we want to be the best. Work hard and be humble.

BILL McKOSKEY

As a senior mechanical engineering student at the U of M, I was papering my apartment walls with rejection letters from all of the fancy, local Fortune 500 companies. One day my mom called and gave me a phone number she saw on a job site sign for Horwitz, Inc. (Yes, my mom found this job for me and reminds me of this fact every time something good happens to me.) That sign included the letters HVAC and she knew I had an HVAC class at some point during my education. One call later I was interviewing at Horwitz, because earlier that same day they discussed hiring a young engineer. Five years later I was a partner, 15 years later I was president, and 30 years later I was handing over the presidential role to Stu McIntosh, enabling me to focus all of my time on sales. Seems like yesterday, but the grey hair and sore joints tell me differently.

Construction was a foreign language to me when I started, but I enjoyed the challenge of learning this new language and I was enthralled by the competitive manner in which a contractor acquires work. Under my tenure as president, we focused on “growth through diversification,” in an effort to soften the highs and lows of the construction bidding/award process and the external effect of the economy. We added a service department through the acquisition of NSI, added an insulation division through the asset acquisition of Thermech, added a temperature control division through the asset acquisition of Tempco, added an electrical division and millwrights division organically, and added an industrial ventilation division through the asset acquisition of TNC.

Throughout my career at Horwitz, we have worked diligently to improve our product and customer satisfaction by following our corporate values of Safe, Accountable, Professional, Motivated, Can Do and Curious. Our executive team and division leaders have done most of the heavy lifting in taking Horwitz to the next level and growing our team from 75 to over 400.

I am particularly proud to have seen the genesis of Horwitz Full Circle and the Horwitz Wellness Committee. Through Full Circle, our team has donated countless hours and an excess of $500,000 to local charities. Our Wellness Committee has created a Horwitz culture of health that reaches beyond the office doors for all of our teammates.

And lastly, I am grateful for a 30 plus year brotherhood with Joe O’Shaughnessy which focused on building a great company for both our clients and our employees. I look forward to our next 100 years and I am excited to see where the Horwitz millennials take us in the years to come.

GARY MUNGER

I called Gary Johnson in 1982, hoping that his year-old-offer to hire me was still good. I was happy to hear Gary’s response, “Get your butt up here.” I did just that and soon settled into bidding work in the public plan and spec bid market; which at the time was plenty competitive. The better market was in the private sector, which was a slow process requiring contacts and business relationships not readily available for a new guy.

Gary Johnson provided a helping hand by introducing me to one of his contacts – a construction manager from Control Data. At the time, Control Data was introducing a new type of cooling system for a space called “computer rooms.” Over the next 25 years, the clients’ names changed from Control Data to Seagate, VTC, Honeywell and Cypress Semiconductor. The projects evolved into Class 10 clean rooms, D.I. water systems, tool sets and gas bunkers. Horwitz was quick to establish a leading role in this new, high-tech piping marketplace.

Gary Johnson provided a helping hand by introducing me to one of his contacts – a construction manager from Control Data. At the time, Control Data was introducing a new type of cooling system for a space called “computer rooms.” Over the next 25 years, the clients’ names changed from Control Data to Seagate, VTC, Honeywell and Cypress Semiconductor. The projects evolved into Class 10 clean rooms, D.I. water systems, tool sets and gas bunkers. Horwitz was quick to establish a leading role in this new, high-tech piping marketplace.

Key to maintaining a strong presence was establishing a well-trained field crew trained in numerous types of exotic piping systems and installation protocol. These crews were commonly referred to as “clean room fitters.” The vast majority of the Horwitz clean room fitters were a direct result of the training and leadership of Charlie Krautbauer.

During my time at Horwitz, many of the people had a positive influence in my life. In life and in memory, I will always cherish them. When asked about the kind of job I had, I’m quick to respond, “I didn’t have a job or a career for that matter, but I was fortunate to have a passion that I received a pay check for.”

LARRY SWANSON

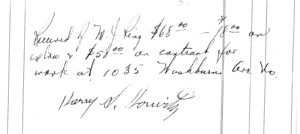

If in 1972, someone predicted that I would end my career at Horwitz serving as president, I would have laughed them out of the room. When I started at H.S. Horwitz, Inc., I thought it might be temporary. Between the recession and my lack of experience, I hoped with some hard work and some good luck, I would overcome these obstacles.

In my experience in estimating and project management at Horwitz, I worked up the ranks, most notably in complex projects such as Target Distribution Centers, design-build at Bloomingdales, other projects at the Mall of America, along with many hotels and multi-residential projects.

As I matured, and as president, my relationship with Horwitz turned into a sort of culture. I was fortunate to work with many good people. I think it’s a testament of the Horwitz culture that many of the quality people I left almost 20 years ago still make up the nucleus of the Horwitz tradition. I’m proud of my mark on the company and the continuance of the traditions that have made the company strong for 100 years.

As I matured, and as president, my relationship with Horwitz turned into a sort of culture. I was fortunate to work with many good people. I think it’s a testament of the Horwitz culture that many of the quality people I left almost 20 years ago still make up the nucleus of the Horwitz tradition. I’m proud of my mark on the company and the continuance of the traditions that have made the company strong for 100 years.

Congratulations Horwitz on 100 years! You’re proof that traditions and a strong company culture are the cornerstones of longevity. Thank you for letting me be a part of such a great company’s history.

GARY L. JOHNSON

In 1970 as a Dunwoody grad with nine years’ experience as a design engineer in a Mechanical Consulting Engineering office, I was excited at the prospect of my interview with H. S. Horwitz. After a thorough interview with Mayer Krupp and Bud Gruenberg, Mayer asked me, “What if we do not like your work?” My reply was, “No problem, I will find another job the same day.” He replied, “You are hired.” From that day forward, Horwitz became my second family. I quickly learned that whatever Mayer asked me to do, he wouldn’t hesitate to do it himself. His “can do anything” attitude inspired me and led me throughout my career at Horwitz.

At that time, we had two owners, Bud Gruenberg, the son-in-law of Harry S. Horwitz (the founder) and Mayer Krupp, who as a youth was a barber in Duluth. Mayer was the original “Benevolent Dictator” respected by all and the “finest man I ever knew.” They were the foundation and guiding force of this company.

We had one project manager, Orville Throndson, who knew everyone in the nursing home business and worked like a horse, flying around in his Chevy El Camino full of tools and materials. He had worked on many water treatment plants and he started me on the Power Plant at Alma, Wisconsin. One engineer, Bill Brisley, a workaholic, was a driving force in the birth of the design-build business. He had many connections with contractors and developers; he could design any project overnight and get it to fit the owner’s demands. What a mentor he was. One service manager, Al Scheere. One secretary, Blanche Olliffe, a formidable force who guarded the entry and kept the salesmen behind the “swinging door” unless she knew you wanted to see them. A great lady. One bookkeeper, and me… a rookie design engineer. We were doing a lot of apartments, commercial buildings and some waste water treatment plants.

In the mid-1970s, we began doing “design-build” work. The large bank building with an adjacent 24-story tower at 7900 Xerxes Avenue South in Bloomington for Rauenhorst Construction (which was the predecessor of Opus), was the first major “design-build” project in the area and our first venture into the “heat pump” business. This project lead Horwitz to the installation of more than 5,000 heat pumps throughout the area, as well as the “tallest” building in Montana.

In 1981, even with considerable resistance, the design-build work flourished with many happy clients and we grew from the tiny office at 1411 14th Avenue South to a larger building at 5000 North County Road 18, as Horwitz Mechanical. Our workload diversified to include many office, medical, industrial, and hotel buildings and some heavy construction work on coal-fired power plants in Alma, Wisconsin, as well as Coal Creek Station and Antelope Valley Station in North Dakota.

Given our heavy workload, deadlines were commonplace. But one particular deadline stands out in my memory. I was at meeting in the office of Ryan Construction, when I asked the Ryan project manager about another large office building downtown that I had bid. He replied, “I told you to proceed and get the drawings done. We have a 10:00 a.m. meeting tomorrow with the owner and the architect… you need to be there with the plans.” I replied, “WHAT? I do not have plans ready.” “YOU BETTER!!!” he replied.

Back in the office, the “can do anything” mode kicked in… I corralled four guys to help and we went to work all the rest of the day and all night. By 9:00 a.m. the next morning, we had completed a full set of HVAC drawings, including plumbing, for the 10:00 a.m. meeting. The look on the owner’s and architect’s faces when they heard what we had done was “priceless.” That project was the 22-story building down-town on 2nd Avenue that Ryan Construction moved their offices into.

It was my pleasure to be involved with many really great people in the office and in the field during that time of my life for which I am forever grateful.